© 2026 Nikon SLM Solutions AG

The Challenge

Energy-sector components are traditionally constrained by long lead times, complex geometries, and conservative qualification pathways.

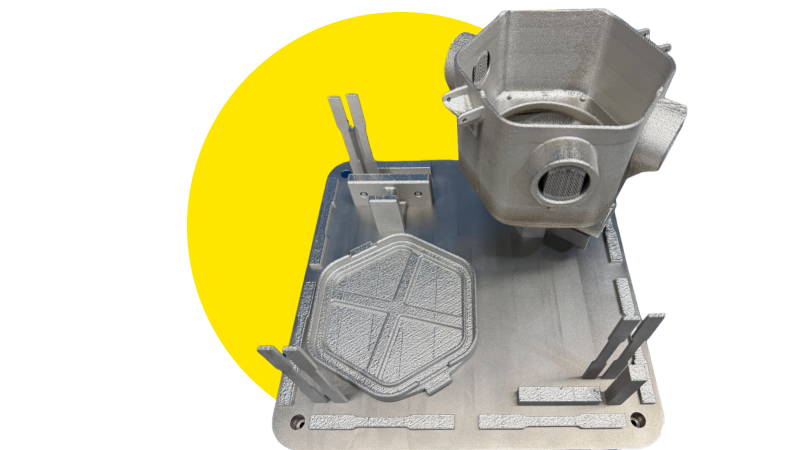

For ExxonMobil, the challenge was not simply producing a part additively—but demonstrating that metal AM could deliver:

The Result

The collaboration demonstrated how metal additive manufacturing can support energy-sector requirements by enabling:

The outcome reinforces metal AM’s role as a production-capable manufacturing technology, not just a development tool.

Download the white paper to learn how to improve suppressor performance and production efficiency.

Quantify the impact of AM on your production. Analyze cost drivers, throughput, and process efficiency to identify performance gains.